| Index & Notes |

|

The breaks we do get on YDI are mostly fitting and service leaks; corrosion

has little to do with a rubber gasket coming loose or leakage around a service

connection that grows from erosion-corrosion. But some YDI has had simple corrosion

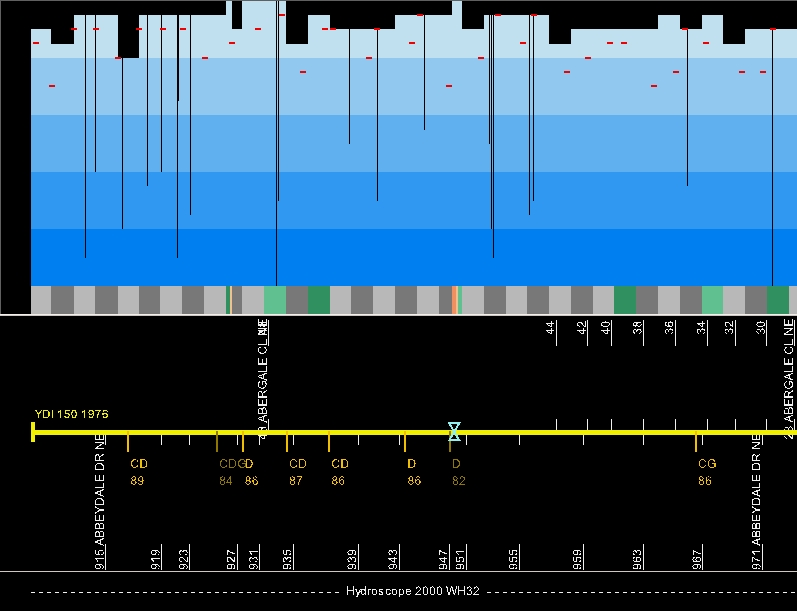

holes and corrosion-related circular breaks. This colourful graph I invented

to show the results of Hydroscope runs - that's a so-called "smart pig"

that you can pull through your mains with a cable, detecting holes and pits

with electromagnetic fields.

The Yellow line at the bottom is the pipe itself, and the ticks on it are the several breaks it has had, this being one of the blocks I mentioned above. The corresponding graph in blue is the pipe wall, the blue bands indicating the 20%, 40%, and so on remaining wall thicknesses. The things that look like mine shafts are individual pits the Hydroscope detected. We believe the problem on this main was that electical shorts occured across from the main to the copper services, letting the current from the anodes drain away so it wasn't protected. Which goes to prove to me that absolutely no coating - not even one five times as thick as polywrap and glued to the pipe - will protect iron unless accompanied by anodes. Jim Bouck was perfectly correct about that.

So far, I haven't mentioned PVC breaks. If we get 200 breaks per year on 500 km of DI and and 30 per year on 600 km of YDI, what's the rate on PVC?