| Index & Notes |

|

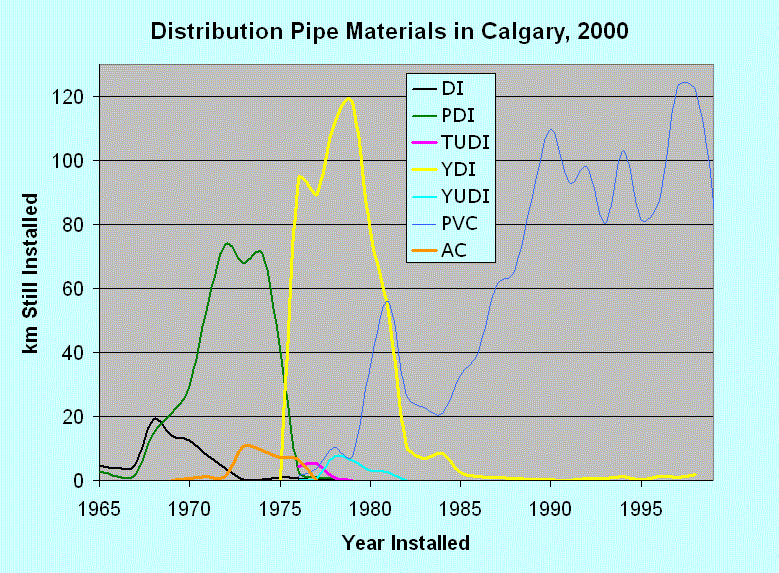

The easy thing to get out of my database is not the full history of what pipe was installed originally, but what is still in the system. In the case of the PVC and YDI lines, it's the same thing, because almost none has ever been replaced. I've left CI out of this picture because I want to focus on our decisions in the 70's that caused our evolution through different pipe materials, and CI predates all that. The installation histogram of PDI, poly-wrapped ductile iron, would have originally been twice as tall; we've pulled out a couple of hundred kilometres of the original 700 or more that went in. Most of it is PDI, the bare DI is the much smaller curve. We started off installing PDI and DI in about equal amounts, but shifted entirely to PDI in the early 70's as corrosion became a concern, while also trying out AC, asbestos cement, which gave us a lot of trouble with "workmanship-related" breaks, and various other DI coatings, like Taped-Urethane DI, and YUDI, yellow-jacketed urethane. But the protection we switched to aggressively was YDI, Yellow-Jacket Ductile Iron, because the great spike in main break rates in the early 70's was largely because of corrosion problems and Calgary was expanding into areas that had much more corrosive soil. We still use YDI, in any location where there is a concern about hydrocarbons ever having been in the soil. But after just 5 years of YDI, we switched again to PVC as the material of choice, and that continues today.

© Calgary Waterworks, 2000 - copyright assigned to AWWA, 2001